Thursday, 23 February 2017

New Technique for Developing Nanodevices at One-Hundredth the Current Cost

Specialists from MIT have grown new methods for building microelectromechanical frameworks at one-hundredth of the present cost.

Microelectromechanical frameworks — or MEMS — were a $12 billion business in 2014. However, that market is commanded by only a modest bunch of gadgets, for example, the accelerometers that reorient the screens of generally cell phones.

That is on the grounds that assembling MEMS has generally required refined semiconductor creation offices, which cost a huge number of dollars to fabricate. Conceivably helpful MEMS have mulled being developed on the grounds that they don't have advertises sufficiently extensive to legitimize the underlying capital interest underway.

Two late papers from specialists at MIT's Microsystems Technologies Laboratories offer trust that that may change. In one, the analysts demonstrate that a MEMS-based gas sensor fabricated with a desktop gadget performs in any event and additionally business sensors worked at routine generation offices.

In the other paper, they demonstrate that the focal part of the desktop manufacture gadget can itself be worked with a 3-D printer. Together, the papers recommend that a generally utilized kind of MEMS gas sensor could be delivered at one-hundredth the cost with no loss of value.

The analysts' creation gadget evades a large portion of the prerequisites that make routine MEMS produce costly. "The added substance assembling we're doing depends on low temperature and no vacuum," says Luis Fernando Velásquez-García, a main research researcher in MIT's Microsystems Technology Laboratories and senior creator on both papers. "The most elevated temperature we've utilized is presumably 60 degrees Celsius. In a chip, you likely need to develop oxide, which develops at around 1,000 degrees Celsius. What's more, by and large the reactors require these high vacuums to forestall tainting. We additionally make the gadgets rapidly. The gadgets we revealed are made in a matter of hours from start to finish."

Welcome resistance

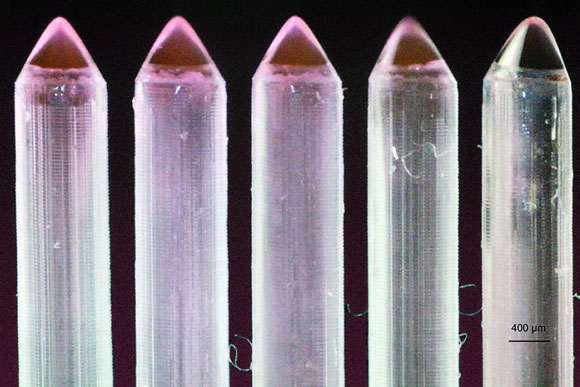

For a considerable length of time, Velásquez-García has been looking into assembling systems that include thick varieties of emitters that discharge tiny surges of liquid when subjected to solid electric fields. For the gas sensors, Velásquez-García and Anthony Taylor, a meeting scientist from the British organization Edwards Vacuum, utilize purported "inside nourished emitters." These are emitters with tube shaped bores that permit liquid to go through them.

For this situation, the liquid contained little chips of graphene oxide. Found in 2004, graphene is an iota thick type of carbon with amazing electrical properties. Velásquez-García and Taylor utilized their emitters to splash the liquid in a recommended design on a silicon substrate. The liquid immediately vanished, leaving a covering of graphene oxide drops just a couple of many nanometers thick.

The drops are thin to the point that collaboration with gas particles changes their resistance quantifiably, making them valuable for detecting. "We ran the gas sensors straight on with a business item that cost several dollars," Velásquez-García says. "What we indicated is that they are as exact, and they are quicker. We make requiring little to no effort — presumably pennies — something that fills in and also or superior to the business partners."

To create those sensors, Velásquez-García and Taylor utilized electrospray emitters that had been assembled utilizing traditional procedures. Notwithstanding, in the December issue of the Journal of Microelectromechanical Systems, Velásquez-García reports utilizing a reasonable, astounding 3-D printer to create plastic electrospray emitters whose size and execution coordinate those of the emitters that yielded the gas sensors.

Made to arrange

Notwithstanding making electrospray gadgets more financially savvy, Velásquez-García says, 3-D printing additionally makes it simpler to alter them for specific applications. "When we began planning them, we didn't know anything," Velásquez-García says. "Be that as it may, toward the finish of the week, we had perhaps 15 eras of gadgets, where each outline worked superior to the past renditions."

Without a doubt, Velásquez-García says, the upsides of electrospray are less in empowering existing MEMS gadgets to be made all the more efficiently as in empowering entirely new gadgets. Other than making little market MEMS items financially savvy, electrospray could empower items contrary with existing assembling methods.

"Sometimes, MEMS makers need to trade off between what they expected to make, in view of the models, and what you can make in view of the microfabrication systems," Velásquez-García says. "Just a couple of gadgets that fit into the portrayal of having vast markets and not having below average execution are the ones that have made it."

Electrospray could likewise prompt to novel organic sensors, Velásquez-García says. "It permits us to store materials that would not be perfect with high-temperature semiconductor fabricating, as natural atoms," he says.

"Without a doubt, the paper opens new specialized ways to making gas microsensors," says Jan Dziuban, leader of the Division of Microengineering at Wroclaw University of Technology in Poland. "From a specialized perspective, the procedure might be effortlessly adjusted to mass manufacture."

"Yet, encouraging outcomes must be demonstrated measurably," he alerts. "Individual experience reveals to me that a lot of exceptionally encouraging materials for new sensors, using nanostructured materials, which have been distributed in abnormal state logical papers, haven't brought about solid items."

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment